MAJA

Contact: Mr. Li

Mobile: 13817371428

Landline: 021-69896133

Website: m.ytrans.cn

Address: Qingpu District, Shanghai Green Pine Road 3562

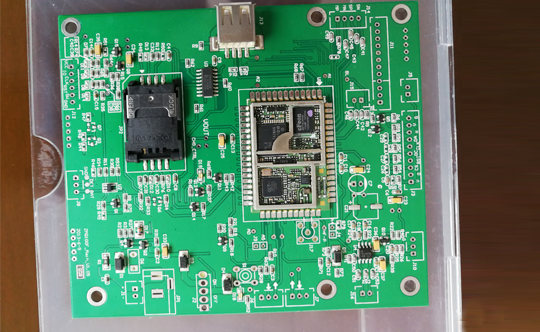

What is SMT chip processing "red plastic" process? In fact, the correct name should be SMT "Dispensing" process. Since most of the glue is red, it is commonly known as "red glue". In fact, it also has a yellow glue. This is what we often call the " solder mask "is" green paint "is the same reason. Reference to the above picture shows the resistor, capacitor and these small parts can be found in the middle of a small group of red jelly objects, this is the red plastic, which was originally designed to stick the parts on the circuit board, The board is then passed through a wave soldering oven to allow parts to be tinted and bonded to the pads on the board without falling into the hot wave solder pot.

The red glue was originally developed because there were so many other electronic components that could not be immediately transferred from the original DIP package to surface mount (SMD) packaging. Imagine a circuit board with half of the DIP parts on top and the other half SMD parts. How do you place the parts so they can be soldered to the board automatically? The usual practice is to design all DIP and SMD parts on the same side of the board. SMD parts are printed on solder paste with solder paste and the remaining DIP parts are exposed on the other side of the board because of all the solder joints , So you can use the wave soldering process all the DIP solder joints are welded together.

Later, a clever engineer came up with a way to save space on the board, is to find ways to put the parts on the side of the original only DIP parts without any parts, but most SMT chip manufacturers DIP parts because the body has too Many gaps, or parts of the material can not withstand the high temperature tin furnace, it can not be placed on the board over the tin side, and the general SMD parts because it has been designed to withstand Reflow temperature, and even immersed in the wave solder pot In a short period of time will not be a problem, but there is no way to print solder paste SMD overwhelming soldering furnace, because the temperature of the solder pot must be higher than the melting point of solder paste temperature, SMD parts will be because the solder paste melts Fell into the tin furnace tank.

Of course, later engineers remembered the use of thermosetting glue to attach SMD parts, which require heating to cure, just to use the Reflow oven so that the problem of falling parts of the tin can be solved and red gum is born , So the circuit board size has been further reduced.

Phone:+86 21-69896133 A company site: Qingpu District, Shanghai Green Pine Road 3562

Two companies: Anting Town, Shanghai Caoan Road 4514, Lane on the 3rd